Cooled

Gate Inserts

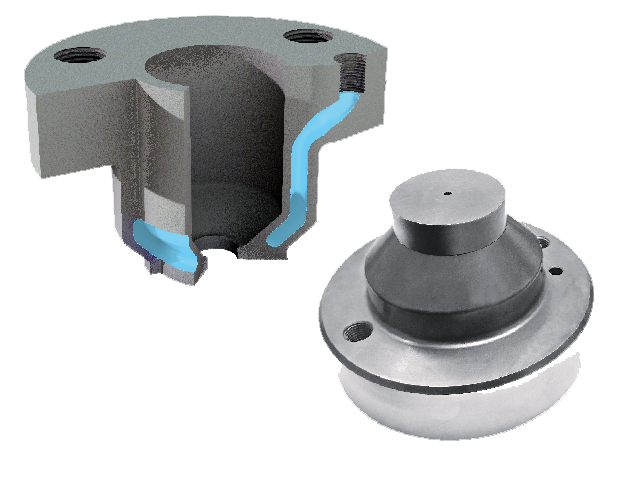

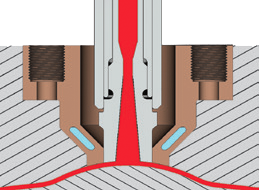

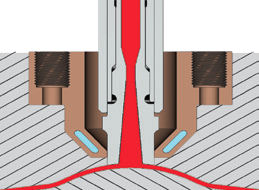

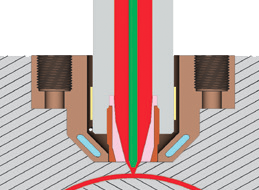

DME’s Conformal Cooled Gate Bushing brings new capabilities to hot runner systems. You achieve greater control of the gate region which can eliminate splay, stringing, reduce warpage and of course, shorten cycle time. Achieve lower piece price and provide superior product with minimal investment.

Benefits

Reduce Cycle Time

Shorten cycle time to increase a tool’s productivity.

Reduce Gate Blemish

Greatly reduce gate blemish such as splay or warp, even stop stringing.

Press Flexibility

Expand press flexibility by achieving greater control of pressures.

Download Information

DME Cooled

Gate Insert

DME’s Conformal Cooled Gate Bushing brings new capabilities to hot runner systems. You achieve greater control of the gate region which can eliminate splay, stringing, reduce warpage and of course, shorten cycle time. Achieve lower piece price and provide superior product with minimal investment.

Applications range from automotive, such as lenses, to packaging like soup cups or lids and everything in-between. Benefits of conformal cooling now available without the need for an analysis process through standard conformal cooling components.

Features

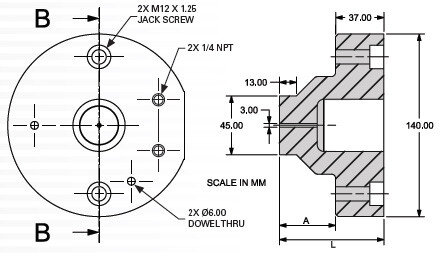

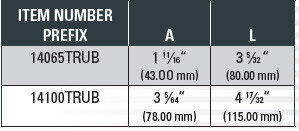

DME Cooled Gate Bushing are a universal fit for multiple molding options and scenarios. They are supplied with surplus stock in the center bore. This allows the end user to mill a precise fitting orifice to house a wide variety of different drop shapes and configurations. The face of the insert also has surplus stock which allows you full control in the way that the face of the insert mates with the mold and/or resin part.

Intuitive Flexibility

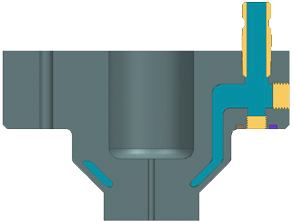

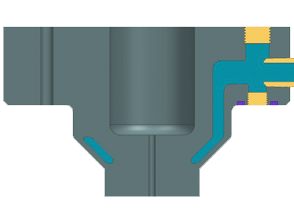

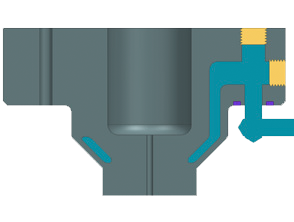

Our standard cooled gate bushing has been developed with the molder in mind. Multiple options for coolant delivery as well as flexibility in melt entrance design allows for use in a wide range of applications

Optional Inlet Configurations

NPT threaded inlet on top.

NPT threaded inlet on side.

O-Ring inlet on bottom.

Face Configuration – Universal Fit

Exposed face (shown with contour)

Blind face with exposed drop tip.

Blind face with valve gate.

MORE PARTS – BETTER QUALITY:

BY INCORPORATING DME CONFORMAL COOLED

COMPONENTS

Using DME’s latest technology to harness greater control of your tool, you can be a step above competition with superior product while reducing cost, waste and time.

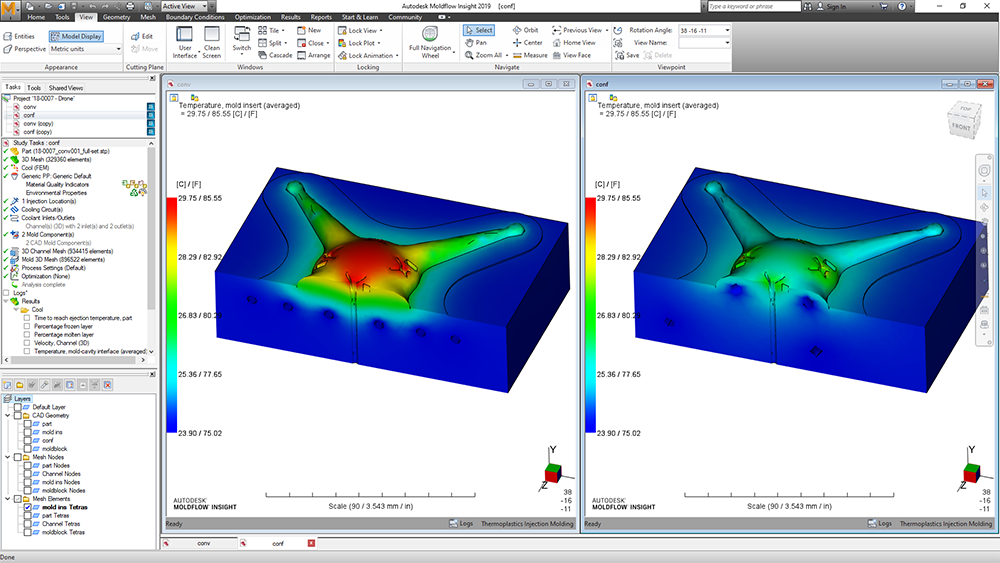

Let The Experts at DME Run Mold Flow Analysis

The skilled team at DME can review an existing project, or a new one coming soon and determine if a conformal cooled gate bushing will provide benefits to your mold.

Optional Inlet Configurations

Contact Us

SERVICES

Hot Runner Service & Repair

Controller Repair & Calibration

ProService (CoolingCare)

Application Engineering

Mold Flow Services

Barrel Repair & Resleeving

Contour Roughing

SUPPORT

Customer Support

Order Support

Documentation

Terms of Sale

Return

FAQ

Credit Application

Worldwide: +1.248.398.6000

USA: +1.800.626.6653

Canada: +1.800.387.6600

Mexico: +52.442.713.5666

Europe: +32.15.215011

Asia: +86.775.8601.9031