Services

Augmenting our superior product line is our expert Service Teams which provide customers with unrivaled knowledge, expertise, and service to help them meet their own customer’s needs. Our journey is a never ending one and we keep innovating to keep ahead of competition and be a position to surpass our customers expectations.

For more information

DME Americas

Engineered Services

DME offers both standard and non-standard mold technologies. Custom solutions are available through our dedicated technical specialists who can provide technical advice, fast quotes and the assurance of receiving a quality product. The DME Engineered Solutions & Services group works with the DME locations worldwide to offer the industry’s widest range of engineered solutions supported locally with our specialized technical service team. Leveraging its 80 years of mold technology experience and its global capabilities DME is ideally positioned to deliver the best value in terms of performance and delivery.

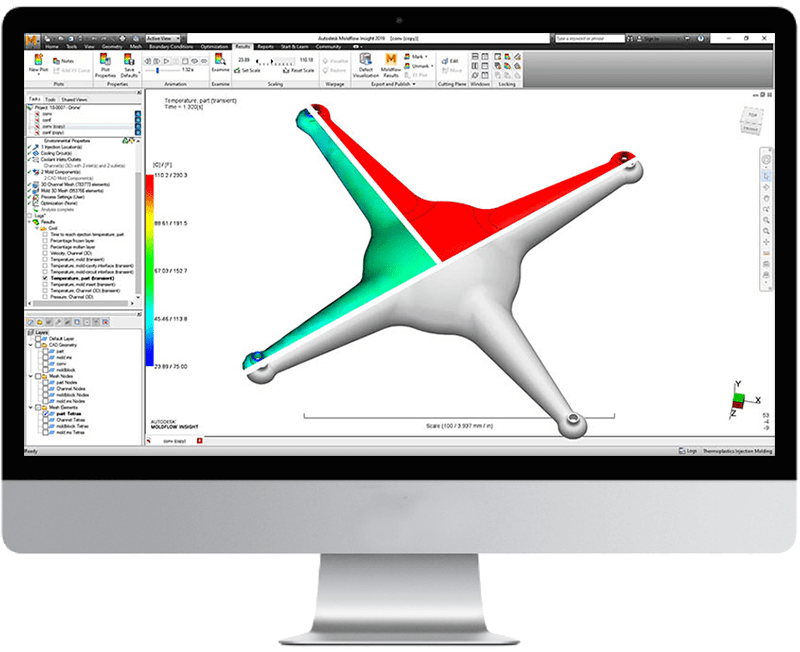

Application Engineering

DME Services

DME’s Applications Engineering Department is focused on one thing – to help you produce better parts. DME customers worldwide utilize our applications engineering expertise for:

- Mold Bases and Specials

- Components or Mold Action Device

- Hot Runner Systems

- Temperature Controls

- Quick-change Molding Systems

- MRO Products

- Die Sets

- Die Cast Tooling

…and more.

A keen focus on our customers is a major reason why DME remains the standard-setter in tooling technology against which all others are compared.

Contact DME by clicking the button below, to move forward on your next initiative.

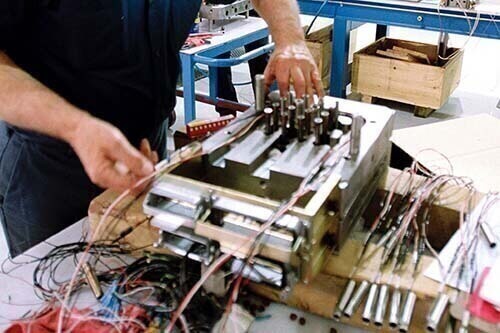

Hot Runner Services & Maintenance

From single nozzles to fully assembled hot halves … and everything in between

Quick, cost-effective hot runner service

DME is committed to help you optimize the performance of your hot runner systems. Applying the knowledge we’ve gained over nearly 30 years of providing hot runner technology to customers worldwide, the DME hot runner service center continues to deliver fast, cost-effective service.

Click the More Info button for a detailed look at DME’s North American Hot Runner Service Center.

ProService (CoolingCare)

Professional, One Day, Diagnostic & Channel Cleaning Service

DME CoolingCare Pro is an inexpensive, worry free opportunity to experience the benefits of a DME CoolingCare unit in a one day trial.

ProService Benefits Include:

- Clean (1) tool with up to 6 cooling channels

- Cleaning media to address various contaminates ($100.00 value)

- On site service technician ($800.00 value)

- No inventory or storage concerns

- DME coordinated round-trip transportation†

- Try-it before you buy-it

- Avoid capital expense approvals

- Service provided in your shop. No need to send the tool out to be cleaned

- Guaranteed improvement of your tool or the service fee is refunded

For more information on our CoolingCare ProService download the PDF information below:

Barrel Repair & Resleeving

DME offers a high-quality low price alternative to competitive barrel resleeving and repair options with fast turnaround time to maximize your uptime. Our service is available for D-2 steel, CPM-10V and CPM-420V.

If your barrel is beyond economical repair, DME stocks new barrels in a wide variety of models and sizes with the highest quality and fastest turnaround time in the industry. Contact DME for more information.

For more information on our Barrel ReSleeving services contact a DME Team Member by clicking the button below.