DME ProService

Boost Productivity and Part Quality

Regain your tool’s cooling performance with DME ProService

YOUR COOLEST INVESTMENT EVER!

Featuring:

Benefits of ProService

ProService - CoolingCare

Try-it Before You Buy-it!

Benefits of Scheduled Maintenace

CoolingCare Owner Login (Coming Soon)

Want More Information

You’re Still Turning Out Parts, But Are

Are Constricted Cooling Channels Costing You Time & Money?

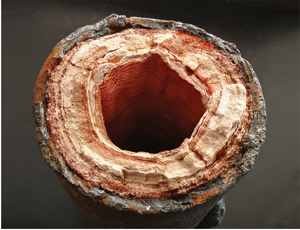

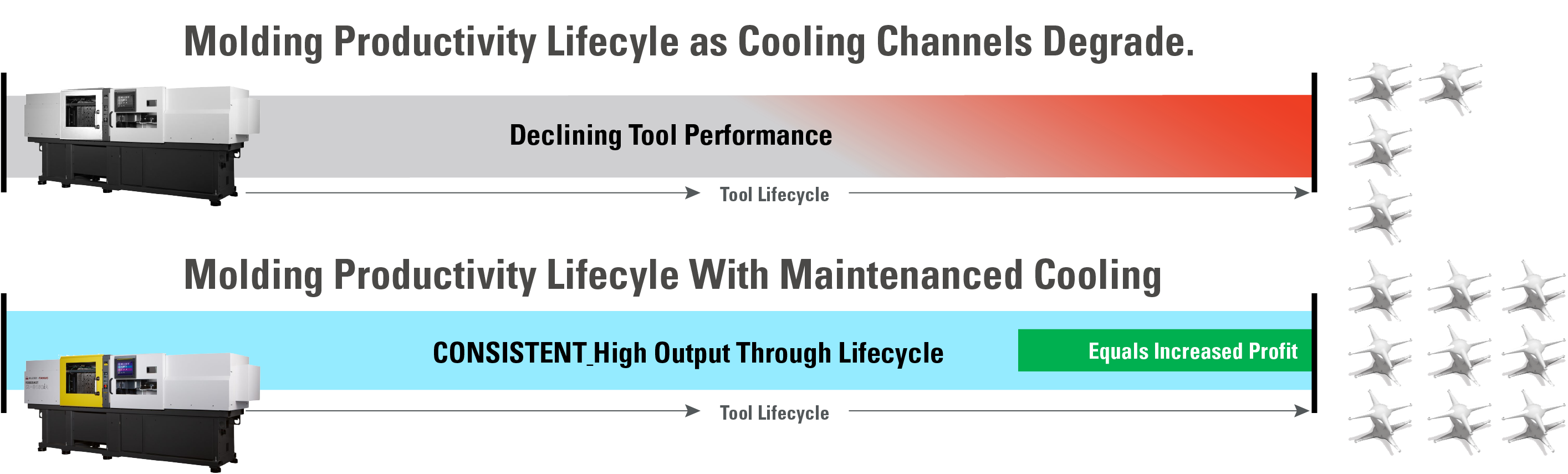

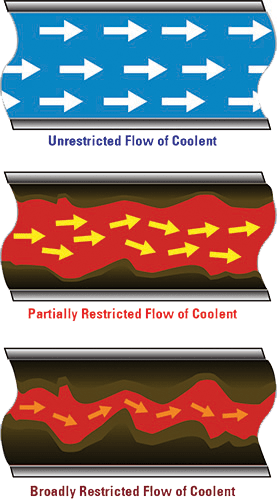

Overtime the cooling performance of the water channels deteriorate with scale and corrosion build up. The result is longer cycle times and quality issues increasing scrap rates. Even with operator adjustments the cooling loss cannot be overcome.

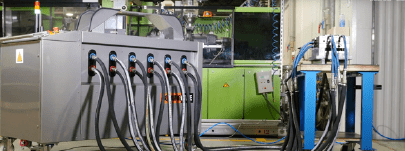

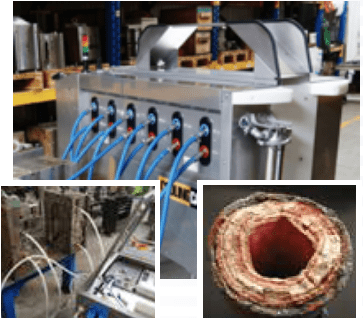

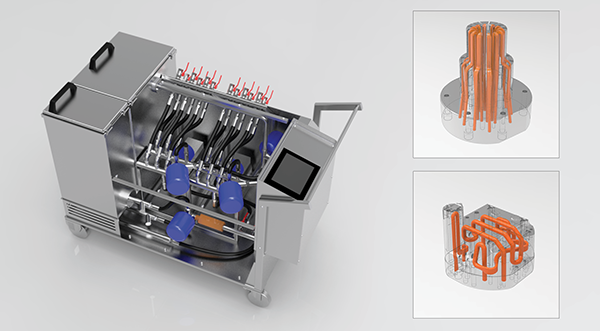

CoolingCare® advanced channel cleaning is the solution to return your tool back to its optimum performance levels. Patented technology combines a chemical and mechanical action to free and dissolve the unwanted material. The control panel with Industry 4.0 capabilities automates the entire process supporting autonomous cleaning without the need for supervision. A simple text message notifies the operators when the process is complete.

Benefits of ProService

A successful molding operation requires the efficient use of all of its, equipment and labor. By managing the cooling performance of the tool part quality, processing cycle times and production up-time can be improved. This can be measured by O.E.E (Overall Equipment Effectiveness) to show the percentage of manufacturing time that is truly productive. Cooling takes up to 50% of the molding cycle making it one of the most important areas to be managed.

Key Benefits ProService Cleaning

Improved flow rate and heat removal capabilities.

- Reducing cycle time

- Increasing production up-time

- Improving part quality

- Reducing maintenance and labor expenses

ProService Overview

- Simply send your tool into DME for a complete cleaning

- DME service technician manage the process

- No inventory or storage concerns

- Guaranteed improvement of your tool or the service fee is refunded

- Opportunity to try out the DME CoolingCare equipment before deciding to buy

ProService

Professional, Diagnostic & Channel Cleaning Service

DME CoolingCare Pro is an inexpensive, worry free opportunity to experience the benefits of a DME CoolingCare unit.

Two Ways To Engage DME ProService

Option #1 – Send It To Us

Send your mold to DME where expert DME ProService Technicians will thoroughly clean your molds cooling system.

ProService Cleanings Include:

- Images of current channel conditions

- Air pressure test to verify channel integrity

- Blockage and water leak tests

- Diagnostics report before cleaning

- Cleaning of water channels by qualified technician

- Diagnostics report after services

- Images of cleaned channels

- Report out of cleaning process

Option #2 – We Come To You

A qualified a DME Technician will come to your site and will provide the following:

ProService Cleanings Include:

- Images of current channel conditions

- Air pressure test to verify channel integrity

- Blockage and water leak tests

- Diagnostics report before cleaning

- Cleaning of water channels by qualified technician

- Diagnostics report after services

- Images of cleaned channels

- Report out of cleaning process

Benefits of Onsite Service:

- Cleaning media to address various contaminates ($100.00 value)

- On site service technician ($800.00 value)

- No inventory or storage concerns

- DME coordinated round-trip transportation

- Try-it before you buy-it

- Avoid capital expense approvals

- Service provided in your shop. No need to send the tool out to be cleaned

- Guaranteed improvement of your tool or the service fee is refunded

For more information on our CoolingCare ProService download the PDF information below:

CoolingCare – Channel Cleaning Solution (overview)

You can also contact a ProService Team Member by clicking the button below.

Contact the DME Customer Service Team

to schedule your hassle free

professional cleaning or simply return

the form on the reverse side and our team

will coordinate a service date.

Toll free US – 800-626-6653

Worldwide – 248-398-6000

Benefits of Scheduled Maintenance

DME understands that uptime and part quality equal money, and a poorly functioning cooling system within a mold base can be costly. Routine maintenance of mold bases keeps tools running consistently and reduces downtime and scrap.

Contact DME today to get more details on DME ProService scheduled maintenance programs.

Example of Return on Investment

-

Weekly Press Revenue (with restricted flow) = $13,500

-

Weekly Press Revenue Improvement (post cleaning) = Overall product output increase 3% = $405 increased revenue

-

Mold Cleaning @ $800/$162 (margin of $405) = ROI in 4.9 weeks

CoolingCare Owner Resources

Coming Soon!

DME offers online resources to registered CoolingCare owners to support the effective use of this amazing tool. If you haven’t received your unique login to our CoolingCare Owner Resources Page please contact our ProService Team to get your login information and start using this resource today!

Contact DME for more information.

Login to your CoolingCare Owners Resoure Page – Use the login credential supplied by DME to access Videos and other CoolingCare resources.