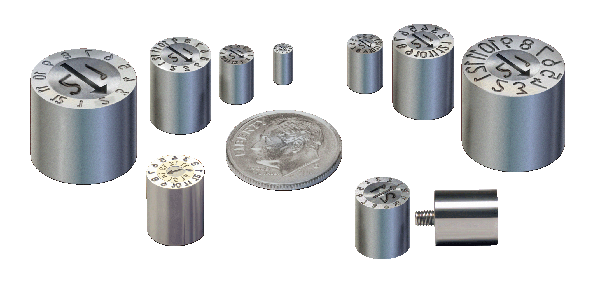

Mold Date Inserts

DME sets the industry standard on mold date inserts by offering the highest quality and most reliable products on the market. When designing your mold select a DME date stamp and you will never miss the mark.

Indexable Mold Date Inserts

Front Removable Inserts

Hi-Temp / Blind Hole Date Inserts

Blind Hole Date Inserts

Dual Ring Mold Date Inserts

New Cumsa MDI Line

SHOP DME ONLINE NOW

EVERY MINUTE, EVERY HOUR, EVERY DAY

EVERY MARK YOU NEED FOR YOUR PRODUCTS

Date traceability, part and resin identification, customer contact and overall functionality of data inserts have been on the minds of DME engineers for years. These simple marking inserts are sometimes an afterthought in the design stages of the mold base however they can provide end user with the most important information about the product and act as a marketing tool.

For these reasons DME has devoted an uncountable amount of hours of R&D to provide traceability solutions to meet today’s market trends and demands.

Dual-Ring Inserts Inner Year Inserts

If you can’t find it lets us know we will make it.

DATE INSERTS

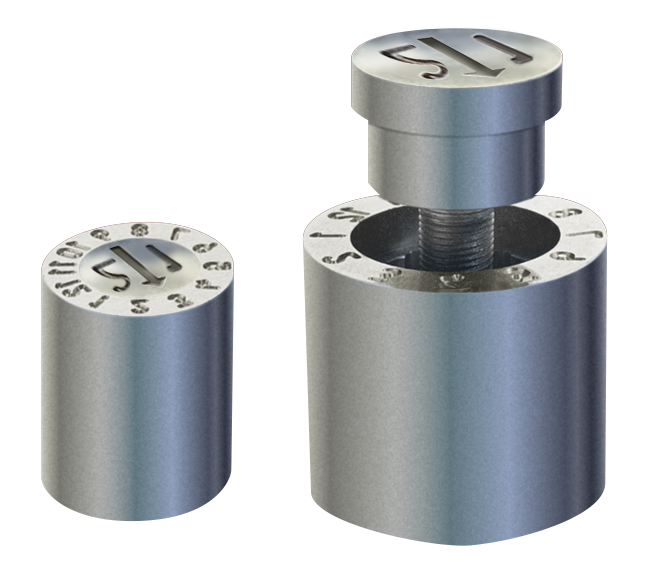

Indexable Mold Date Inserts

DME Indexable Mold Date Inserts (MDI) provide traceability required in part quality programs.

Designed for plastics injection molds.

Offering a distinctive indexable, snap-in-place arrow alignment, Indexable Mold Date Inserts’ unique design keeps the inner insert flush for three full turns.

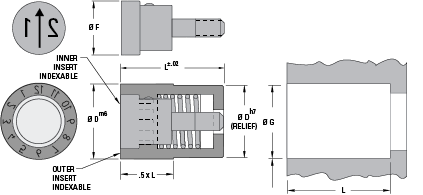

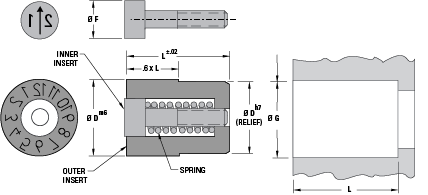

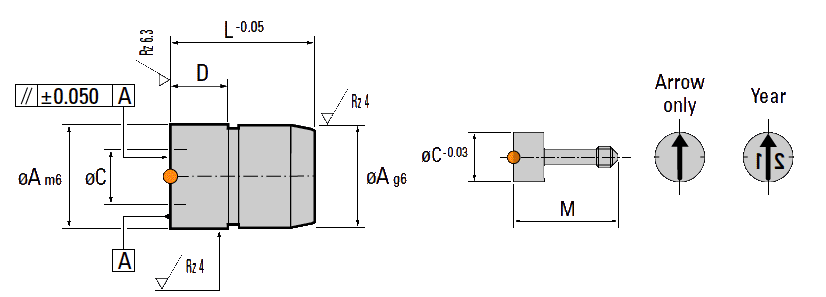

Specifications

- Numerals are 0.2mm deep and arrow is 0.4mm deep

- Arrow is adjustment slot

- Maximum operating temperature is 150°C (300°F)

Installation and Machining:

Press-fit installation required. Maintain a close tolerance press fit. Too loose could allow the insert to move out of position, while too tight a press-fit might prevent the inner insert from rotating when required. Accurately measure the 0D for each part and machine ØG hole to provide about 0.005mm (.0002″) press fit.

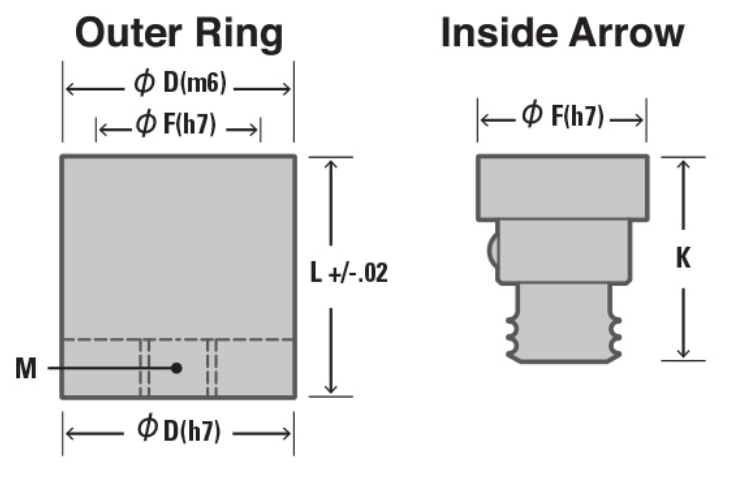

D = Outside Diameter of Outer Insert

F = Outside Diameter of Inner Insert

L = Length

Material: Corrosion-resistant Stainless Steel

Hardness: 53 ± 3 HRC Max. Temp: 150°C (300°F)

Dimensions: All dimensions are in mm, except as noted

Features & Benefits

- Front removable inserts have a replaceable spring to help keep the inner insert from moving during molding.

- Indexable inserts have “captured spring” in the outer insert and a ball detent on the inner insert to help lock the inner insert in place.

- Arrow functions as adjustment slot

- Easily replace or adjust the inner insert while mold is in the press.

- Numerals are 0.2mm deep, arrow is 0.4mm deep

Front Removable Inserts

Front Removable Inserts are designed for injection molds. Easy to replace or adjust the inner insert while the mold is in the press.

- Front removable inserts have a replaceable spring to help keep the inner insert from moving during molding

- Indexable inserts have “captured spring” in the outer insert and a ball detent on the inner insert to help lock the inner insert in place

Installation and Machining: Press-fit installation required. Maintain a close tolerance press fit. Too loose could allow the insert to move out of position, while too tight a press-fit might prevent the inner insert from rotating when required. Accurately measure the ØD for each part and machine ØG hole to provide about 0.005mm (.0002″) press fit.

Features & Benefits

- Easily replace or adjust the inner insert while mold is in the press

- Arrow functions as adjustment slot

Specifications

- Maximum operating temperature is 150°C (300°F)

- Numerals are 0.2mm deep, arrow is 0.4mm deep

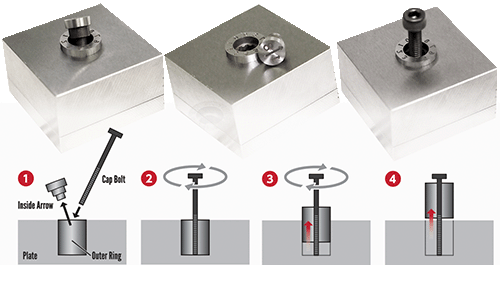

Hi-Temp / Blind Hole Date Inserts

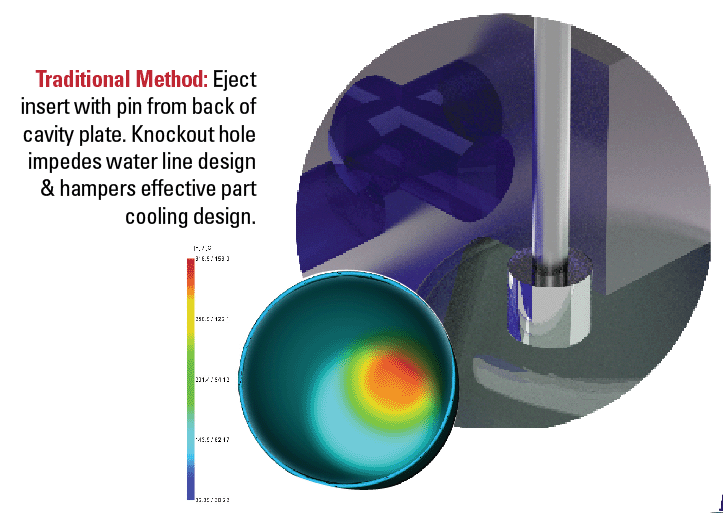

PRODUCTIVITY BOOSTER

Easy Access, Reduced Down Time & Increased Productivity

- Withstands temperatures up to 644ºF (340ºC) enabling use with a broader selection of resins

- Faster easier way to insert & remove inserts thus saving hours in production and down time every year

- Designed to be easily removed from cavity plate with a small screw driver and a metric screw, no need for a thru-hole

- Newly engineered inner inserts are removable with fewer rotations due to shorter threads (not compatible with other DME inserts)

- Inner inserts use ball detents to click into position

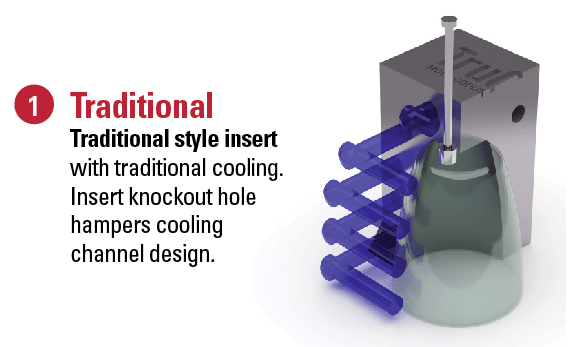

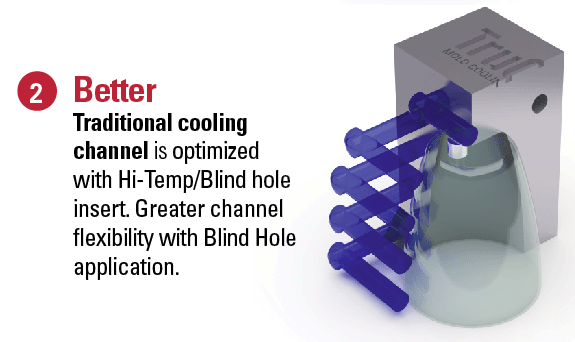

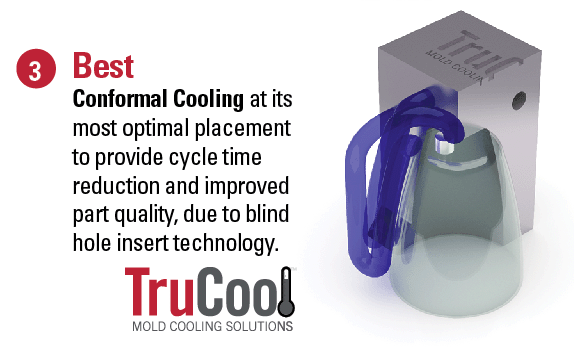

SMALL PACKAGE LARGE THERMAL IMPACT

Design Your Mold With Maximum Thermal Management in Mind

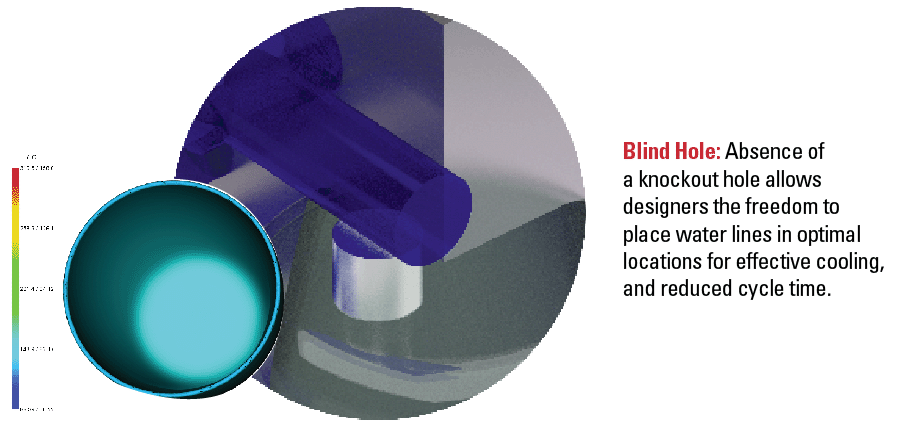

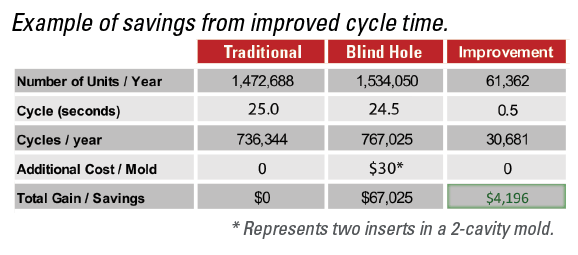

- Improves cycle time due to engineering freedom of the water line placement

- DME’s Hi-Temp inserts are rated at more than twice the max temp of our standard inserts

- Blind hole inserts allow the designer to route cooling lines closer to the core where cooling is critical

- Traditional inserts require a knockout hole to be machined for removal which limits cooling channel location and size. Hi-Temp/Blind Hole inserts maximize design and cooling location options.

- Specific resins require high heat and longer cycle times. Choose the insert that stands up to the heat and allows for optimal cooling for improved cycle times.

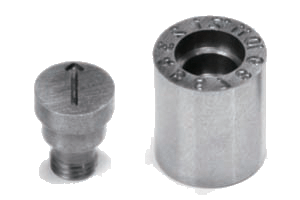

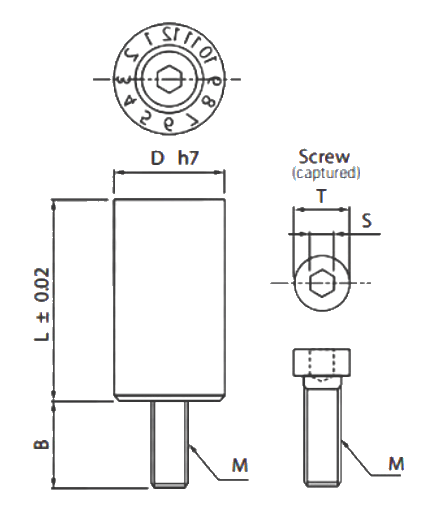

Features & Benefits

- The Hi-Temp/Blind Hole inserts do not require a knockout hole and can be removed from the cavity while the mold is still in the press with a cap screw, no need for a thru-hole.

- Designed to be easily removed from cavity plate with a small screw driver and a metric screw.

- Inner inserts use ball detents to click into position.

Blind Hole Date Inserts

Blind Hole Date Inserts are compatible with standard indexable DME inner inserts.

- Patented mold date insert design

- Thru hole not necessary for removal

Specifications

Features & Benefits

- Patented mold date insert design

- Installs with insert’s captured screw into the mold plate

- Thru hole not necessary for removal

- Changes and maintenance done with mold in the press

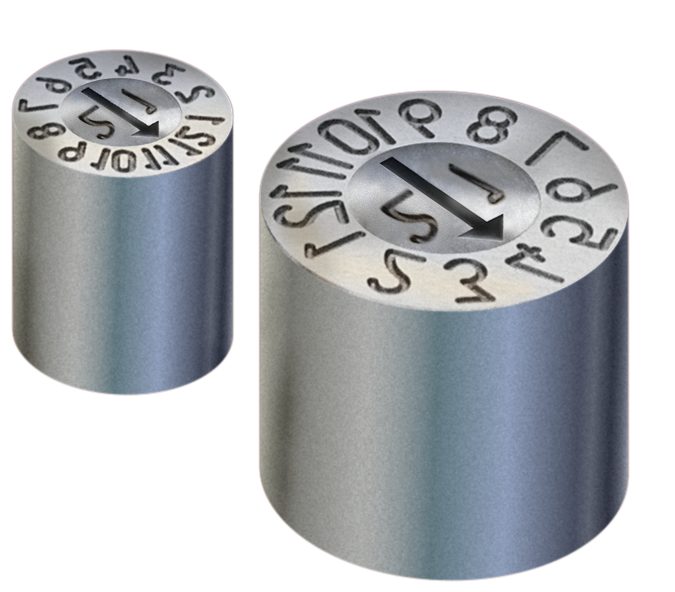

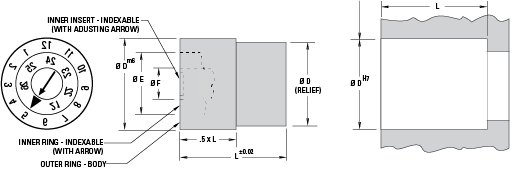

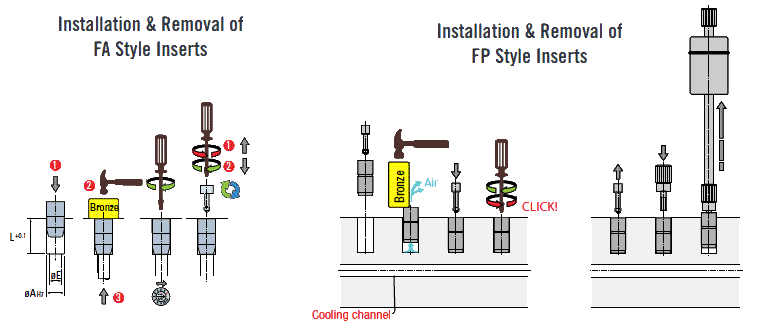

Dual Ring Date Inserts

Dual Ring Date Insert Offers the Ultimate in Date Insert Flexibility.

Patented Indexable Mold Date Insert Technology

The Dual-Ring Mold Date Inserts from DME features a date insert identification valid for six years and is based on Indexable Mold Date Insert technology.

The Dual-Ring Insert eliminates the need to install two date inserts or change the inner insert each year. This easy-to-use indexable insert provides the flexibility you need to keep your mold dates current for up to six years.

- The Dual-Ring Mold Date Inserts from DME features a date insert valid for six years and is based on Indexable Mold Date Insert technology.

- The Dual-ring Insert eliminates the need to install two date inserts or change the inner insert each year. This easy-to-use indexable insert provides the flexibility you need to keep your mold dating current, especially as the lifetime of molds becomes shorter.

Specifications

- Outer ring: 12 months, months 1 through 12

- Inner ring: 6 years + arrow (arrow points to month)

- Center insert: arrow points to year and adjusts position of both arrows

- Dual-Ring Insert may be interchanged for the 20mm, 16mm, 10mm, 8mm to 6mm diameter Indexable and Front Removable inserts

Features & Benefits

- Double indexable: both arrows independently “click into position”

- Change positions easily with only a screwdriver using arrow in inner insert

- All inserts remain flush when rotated

Installation & Machining: Press fit installation required. Maintain a close tolerance press fit. Too loose a fit could allow the insert to move out of position, while too tight a press fit might prevent the inner insert and inner ring from rotating when required. accurately measure ØD for each part and machine hole to provide about 0.005mm (.0002″) press fit.

D = Outside Diameter

F = Outside Diameter of Inner Insert

L = Length

Material: Corrosion-resistant Stainless Steel

Hardness: 53 ± 3 HRC Max. Temp: 150°C (300°F)

Dimensions: All dimensions are in mm, except as noted

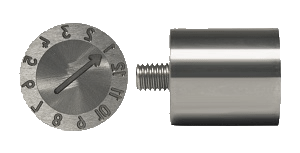

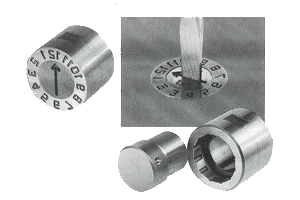

STAY WITH THE PROVEN BRAND

CUMSA MOLD DATE INSERT LINE

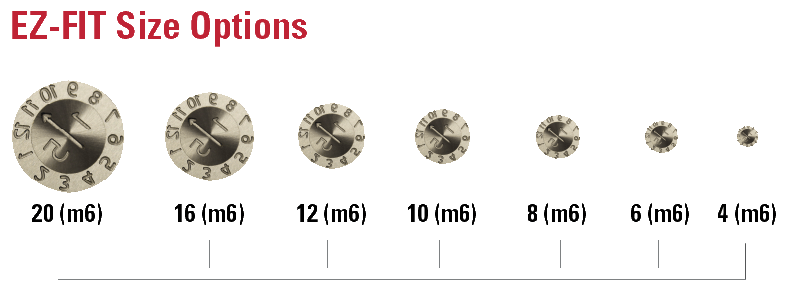

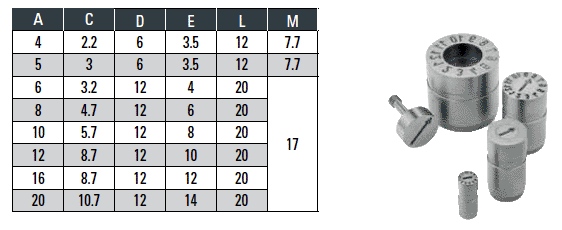

Two standards prevail in the North American market with the DME Standard being preferred due to its smaller size, ease of installation and reliable and long-life performance. CUMSA is the alternative standard. We are pleased to inform you that the original CUMSA product line is available in the U.S. through DME. This completes the DME portfolio and makes us the undisputed world leader in the supply of high quality date and identifier inserts.

Manufactured in Europe to tight tolerance using premium steel, the CUMSA branded products are proven in their performance. Note: it is important not to risk potential product failures and production downtime by using unproven and possibly cheaper alternatives. Look out for the genuine CUMSA marking on your parts to be sure that you receive the same high quality you have been used to year after year.

Features & Benefits

- Inner insert always stays level with the outer ring

- Wide range of diameters available

- Requires only an H7 pocket to install

- Inset change requires no down time

- Internal mechanism ensures secure replacement of insert

Two Models:

- Traditional FA-Style (requires knock-out hole)

- Newly Added FP-Style (doesn’t require knock-out hole. Blind Hole for more convenient cooling line placement)

Inner Year Inserts

Tech. Resources

toll-free US: 800-626-6653

toll-free Canada 800-387-6600

[email protected]

Featured Products

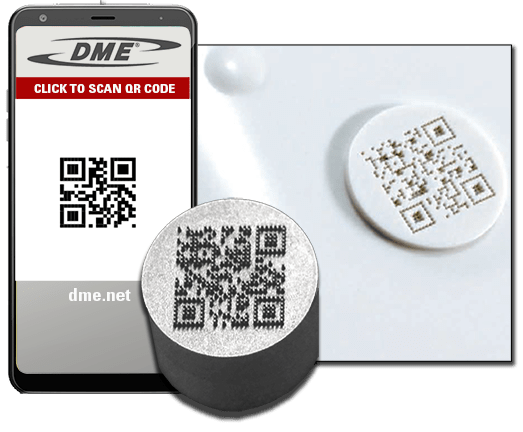

QR-Code Inserts

Add a QR-Code Directly to Products

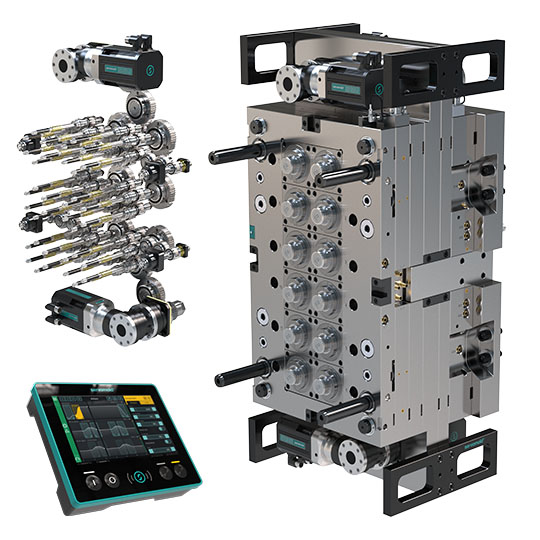

DME CoolingCare

Automatic Maintenance, Diagnostics & Conservation of Cooling Channels

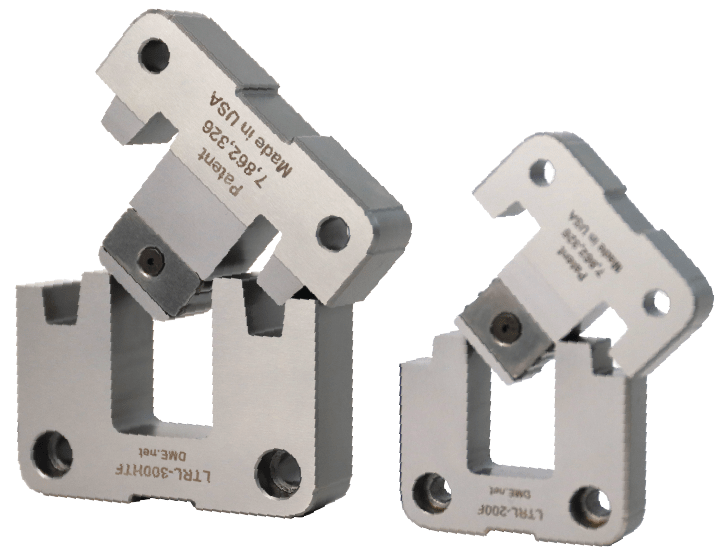

DME LT-Series LifeTime Roller Locks

NEW -Roller Bearing Side Locks available in Hi-Temp and Stainless Steel