DME DURA Core Collapsible Cores

Next-Gen Spring Collapsible Cores

Featuring

Zero Segment Contact During Motion

Patented Two-Piece Design

Straight Core Pin

Diverse Segment Options

DURA Collapsible Core Animation

DURA Core Collapsible Cores

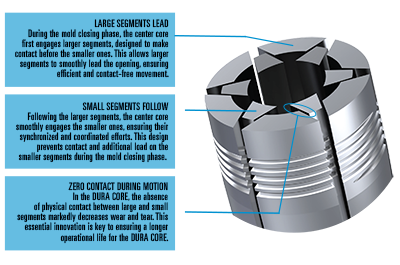

Introducing DURA CORE, an innovative collapsible core solution: a ground breaking two-piece spring collapsible core designed for precision and longevity. This advanced collapsible core features a unique sequential collapse mechanism, where the larger and smaller segments operate independently. This distinct design ensures stress-free movement of the smaller segments, significantly enhancing the life-span of the DURA CORE.

Utilizing our exclusive patented design, every DURA CORE purposefully eliminates interaction between the larger and smaller segments throughout the collapsing process. This ground breaking characteristic not only prolongs the core’s durability but also promotes the production of premium quality parts.

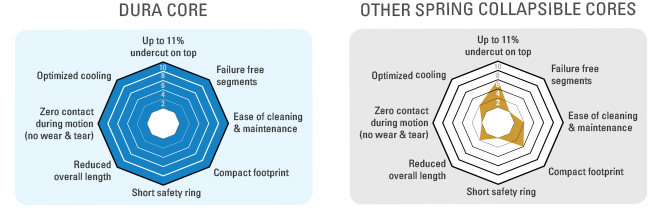

Spring Collapse Comparison

FEATURES

Patented Two-Piece Design

The two-piece design of the DURA CORE is an innovative feature that significantly enhances the usability and maintenance of the collapsible core in injection molding.

Effortless Disassembly: Simplifies the process, enabling quick access to each component

Easy Inspection and Cleaning: Offers enhanced accessibility for thorough maintenance

Rapid, Secure Reassembly: Ensures quick and correct reassembly after maintenance

Minimize Maintenance Downtime: Reduces maintenance time, boosting production

Additional Design Features

Short Safety Ring: A compact safety ring, securely mounted on a safe plate

Straight Core Pin: The straight core pin design is a key element in optimizing both manufacturing and cooling. By facilitating more efficient cooling, it leads to improved overall performance of the core, enhancing the quality of the molded parts.

Reduced Overall Length: The DURA CORE’s reduced length offers considerable space-saving advantages. This design aspect is particularly beneficial in minimizing the mold base stack height, leading to more compact and efficient mold designs.

Compact Footprint: The core’s space-efficient design allows for more cavities in the same-sized molds or the same number of cavities in a smaller mold, thereby maximizing production output per cycle.

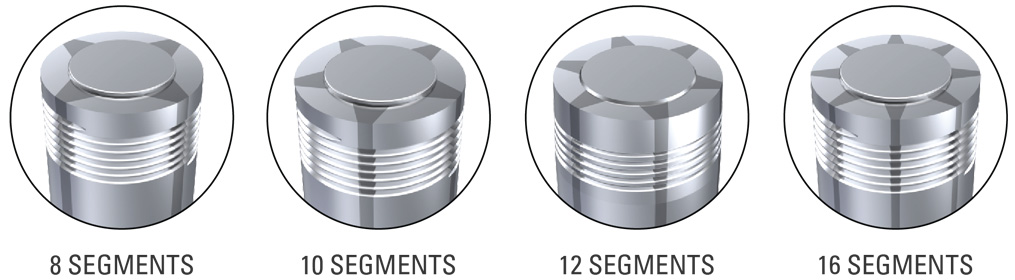

Multiple Segment Options

Depending On Part Geometry

The DURACORE can be designed with diverse segment options, providing design flexibility to ensure sufficient collapse for undercuts. The number of segments required is determined by the part size, part shape and the undercut. We offer options of 8, 10, 12, and 16 segments to accommodate a broad spectrum of part sizes, with diameters ranging from 15mm to 150mm.