Electric Unscrewing Device

- The highest precision & process reliability

- Shortest cycle-times & highest availability

- Clean & oil-free operation (suitable for cleanrooms)

- Maintenance friendly design – long service intervals

- Compact design

Features

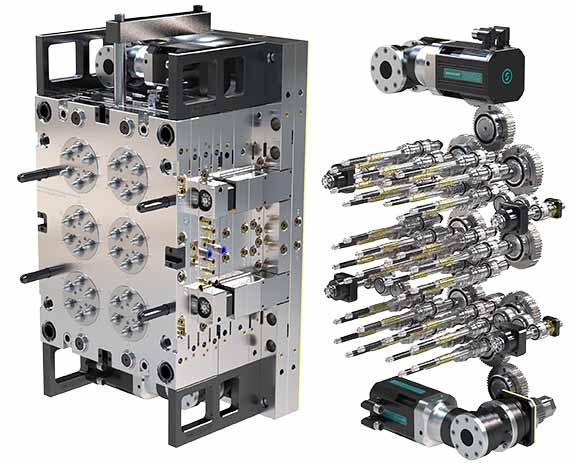

The Clean Solution

Full electric – No Oil – No Leaks. Perfect for Clean Room Facilities.

1 or 2 Gear Box Levels

Systems designed to meet the need.

See It In Action!

Check out video of this device.

Featuring the

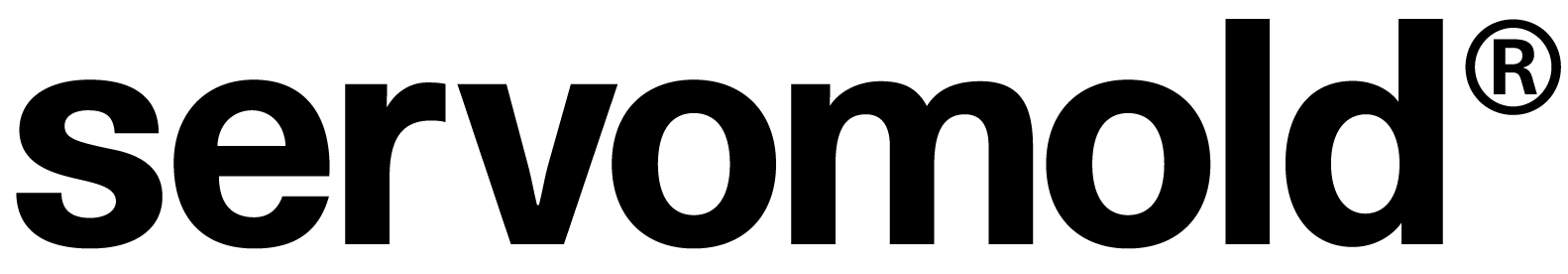

High-performance Servo Unscrewing Devices for Multi-Cavity Molds

Servo unscrewing devices are DME’s answer to the demands made on high-performance injection molds with unscrewing functionality.

The Clean Solution

for Your Injection Molding Tool.

Specifications

1 to 128 unscrewing concepts

See It In Action!

Featuring

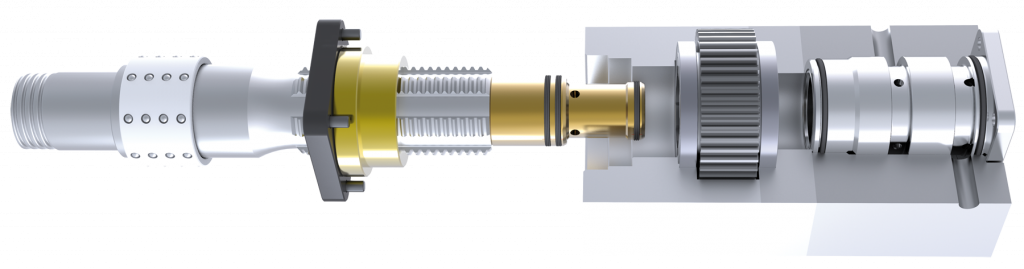

Threaded core, guide thread and cooling insert with sealings.

System Design

1 gearbox level or 2 gearbox levels

- Number of cavities

- Thread size and length and thus maximum breakaway torque

- Cavity spacing and arrangement of the cavities

- Required unscrewing speed

System design is typically handled by project engineers, taking into account the technological possibilities and complying to the customer requirements.

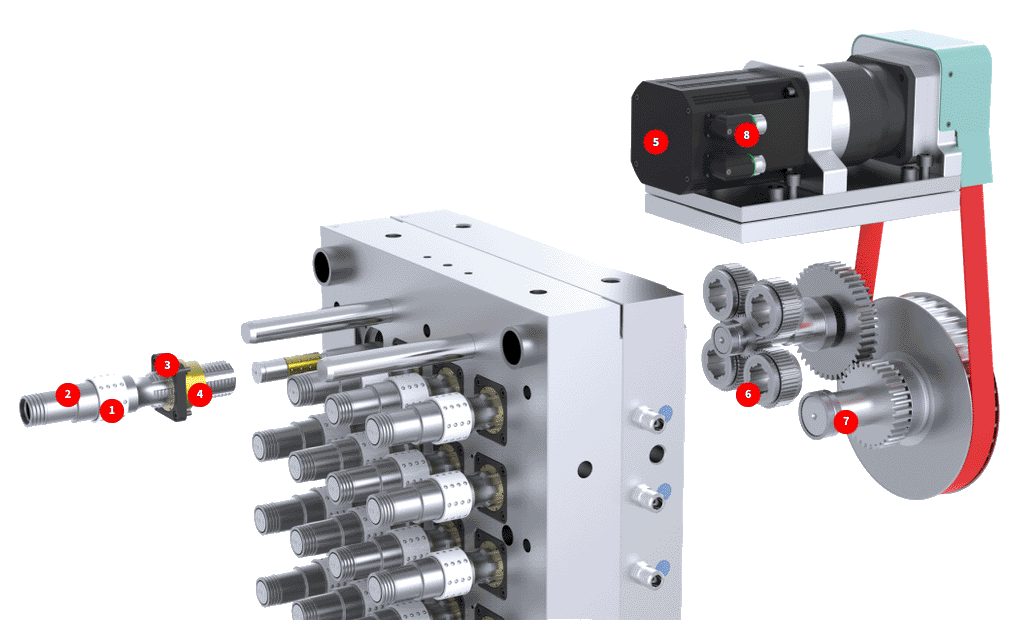

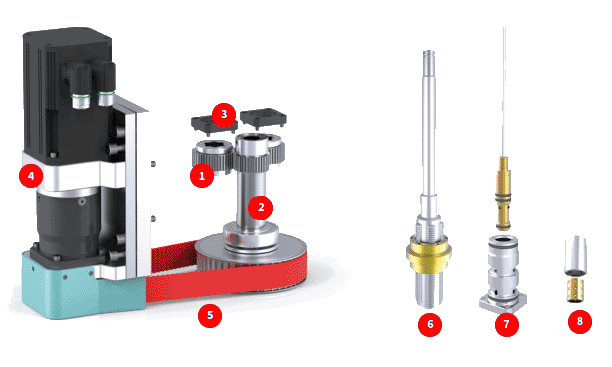

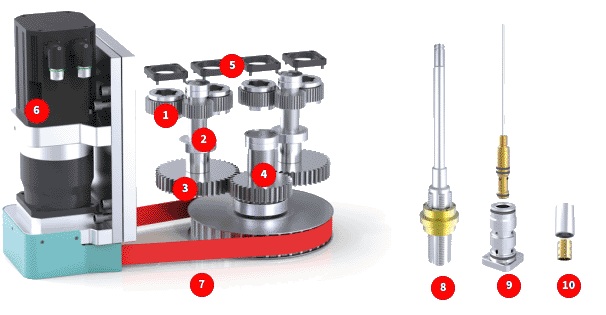

Overview of device includes:

- Ball cage

- Threaded core or threaded sleeves

- Guide nut

- Guide thread

- Servo multi-drive SMA

- Gearbox level 1 with spur wheel

- Gearbox level 2 with timing belt disc, pinion shaft and driving pinion

- Motor plug

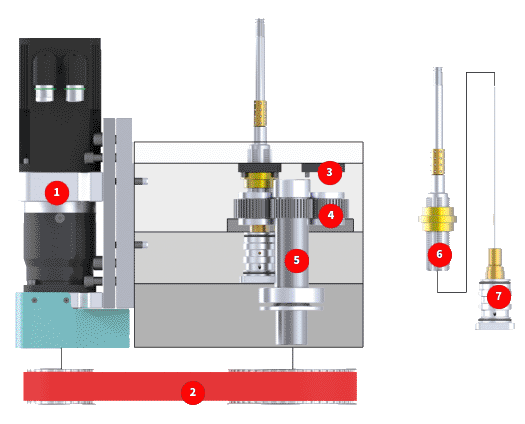

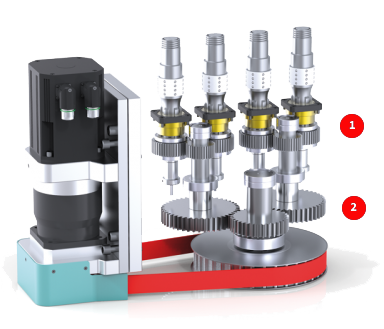

System Design 1 Gearbox Level

In servo unscrewing devices with one gearbox level, several spur wheels are driven by a central pinion shaft RZW. For the design of the system by our project engineers the following information (if available) is needed and applied:

Plastic part

- Thread diameter and length

- Wall thickness and calculated shrinkage

- Type of plastic and fillers

Injection mold

- Maximum tool size and tool height

- The number, layout and desired distance of the cavities

- Threaded cores with cooling

Process

- Mold and melt temperature

- Unscrewing time and overall cycle time

- Cleanliness level (clean zone, clean room)

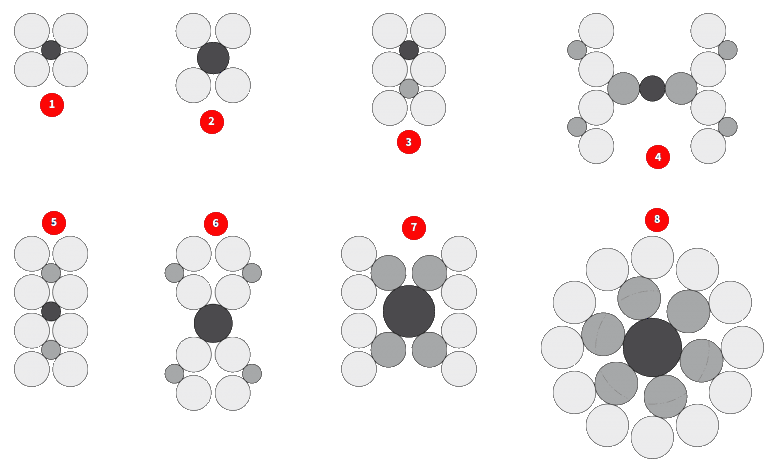

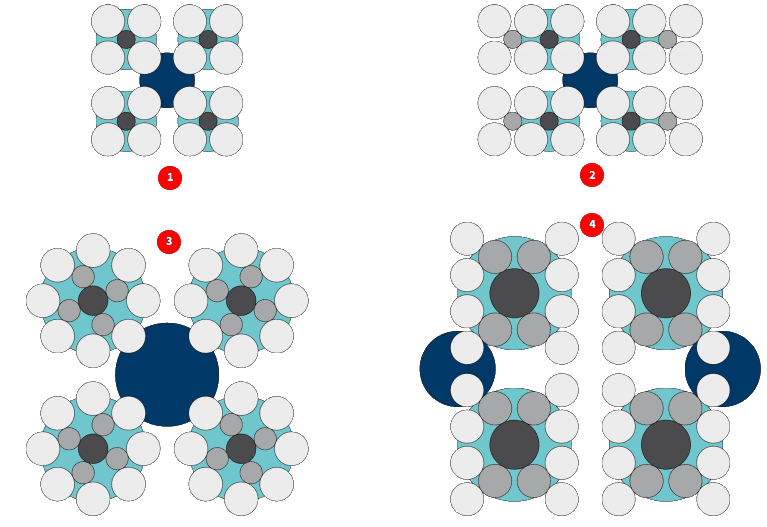

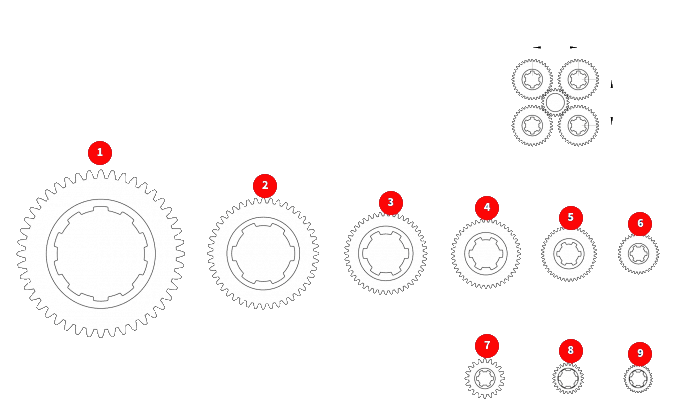

The following figure illustrates arrangement examples of systems with one a single level of gears.

- The cavities can be arranged in a square, rectangular or circular pattern

- Execution of the threaded cores and optional cooling according to customer specification:

- Servo Multidrive SMA

- Servo timing belt unit SZE

- Clamping plate LMP

- Spur wheel STR

- Pinion shaft RZW

- Threaded core set

- Cooling option RKE

The following figure illustrates arrangement examples of systems with one transmission level.

- 4x symmetrical

- 4x asymmetrical

- 6x symmetrical

- 8x asymmetrical

- 8x symmetrical

- 8x asymmetrical

- 8x asymmetrical

- circular

Note: This circular arrangement of pinions is perfect for very compact, high cavity mold design. This can be accomplished with only one gearbox level (8x, 16x). The gating is done with MoldMaster’s Melt Disk.

Sample (Scope of delivery) System Components 4x SAM

- 4x Spur wheel STR incl. bearings

- 1x Pinion shaft RZW incl. bearings

- 4x Clamping plate LMP

- 1x Servo multidrive SMA

- 1x Servo timing belt unit SZE

- Plus 4x threaded core set

- Plus 4x cooling option

- Plus 4x ball cage option

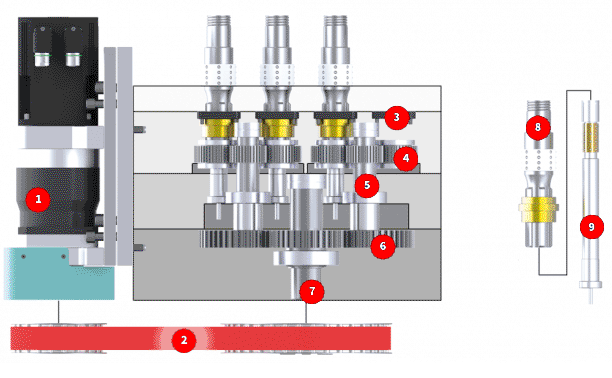

System Design 2 Gearbox Levels

These are coupled with the pinion shafts of the first gearbox level which are driving several spur wheels.

Our Design Engineers can help determine the optimum system configurations for your application using the following parameters:

• Plastic Part • Injection Mold • Process

- 1st gearbox level

- 2nd gearbox level

The following figure demonstrates the standard setting for the system design with two gearbox levels.

- The cavities can be arranged in a square, rectangular or circular pattern.

- Execution of the threaded cores and optional cooling according to customer specifications.

- Servo-Multidrive SMA

- Servo timing belt unit SZE

- Clamping plate LMP

- Spur wheel STR

- Pinion shaft 1 RZW-1

- Pinion RTZ

- Pinion shaft 2 RZW-2

- Threaded core set

- Cooling option STI

The following figures illustrates arrangement examples of systems with two levels gears.

- 16x symmetrical

- 24x asymmetrical

- 32x – circular

- 2x – 8×4 rows

Note: This circular arrangement of pinions is perfect for very compact, high cavity mold design. This can be accomplished with only one gearbox level (8x, 16x). The gating is done with MoldMaster’s Melt Disk.

Sample (Scope of delivery) System Components 16x SAM

- 16x Spur wheel STR incl. bearings

- 4x Pinion shaft RZW-1 incl. bearings

- 4x Pinion RTZ

- 1x Pinion shaft RZW-2 incl. bearings

- 16x Clamping plate LMP

- 1x Servo-Multidrive SMA

- 1x Servo timing belt unit SZE

- Plus 16x threaded core set

- Plus 16x cooling option

- Plus 16x ball cage option

Standard & Special System Sizes

- SAM120144 Z44 M3,00

- SAM080096 Z44 M2,00

- SAM060072 Z44 M1,50

- SAM050060 Z44 M1,25

- SAM040048 Z44 M1,00

- SAM030038 Z36 M0,90

- STR Z20 M1,50

- STR Z24 M1,00

- STR Z32 M0,70

Want to Know More!

Reach out to DME today.

For all inquires please contact DME at:

[email protected]

Toll-free U.S. – 800-626-6653

Toll-free Canada – 800-387-6600

Worldwide – 248-398-6000

[email protected]

NO MATTER WHAT YOUR NEEDS DME HAS YOU COVERED.

Worldwide:

+1.248.398.6000

USA:

+1.800.626.6653

Canada:

+1.800.387.6600

Mexico:

+52.442.713.5666

Europe:

+32.15.215011

Asia:

+86.775.8601.9031

SUPPORT

Customer Support

Order Support

Documentation

Terms of Sale

Return

FAQ

Hot Runner Service & Repair

ProService (CoolingCare)

Application Engineering

Mold Flow Services

Barrel Repair & Resleeving